- ParkOhio Supply Technologies Group

-

- RB&W

- Supply Technologies

RB&W

RB&W Corporation, a key member of the ParkOhio family, stands as a pioneer in cold-forming technology and ranks amongst the largest producers of cold-formed parts in the U.S. Established in the mid-19th century, the company's engineering prowess has consistently delivered innovative manufacturing solutions to a host of industries worldwide.

From its early involvement with the nascent transportation industry to today, RB&W's cold-formed and manufactured fastener products are integral components in millions of vehicles, marking hundreds of crucial applications. The automotive and automotive aftermarket industries heavily rely on the company’s robust offerings.

Tracing its origins to the collaboration of William Evans Ward and Ellwood Burdsall, the company, known as Russell, Burdsall & Ward Bolt, and Nut Company, revolutionized fastening by moving from manual blacksmithing to mechanized production. RB&W continued its innovation journey, introducing the world's first automatic, solid die cold-heading machine in 1850, a marvel now housed at the Henry Ford Museum in Michigan.

Through strategic acquisitions and adaptability, RB&W evolved, shifting its focus from standard products to specialty-engineered parts in response to changes in the fastener industry. The company became a part of ParkOhio in 1995, further solidifying its role in delivering high-quality, specialized solutions for various industries.

Product Snapshot

RB&W Corporation's extensive product line offers an impressive variety of top-tier cold-formed parts and engineered fasteners. Catering to the global automotive industry, RB&W delivers custom and specialized component solutions that meet exact requirements.

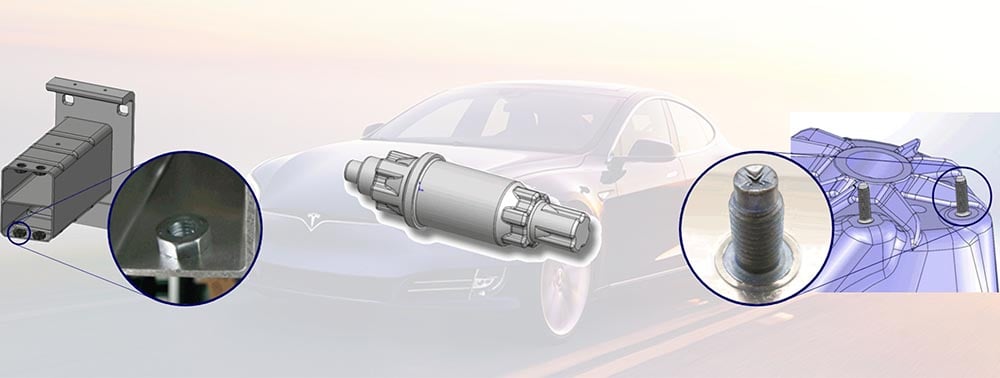

RB&W Corporation specializes in lightweight alternatives to welded joint solutions in electric vehicle (EV) applications where weight is a concern. Their specialized R&D team works closely with the OEMs on their future designs to incorporate the fasteners to meet precise performance specifications.

Their SPAC® (Self Pierce and Clinch) Aluminum Fastening offers their customers a solution that will avoid corrosion and cracking while eliminating the need to weld. This cold-forming process is a viable, cost-effective alternative to screw machining, hot forging, and casting.

With a commitment to technological innovation and quality, RB&W continues to meet and exceed industry standards, ensuring customer satisfaction and delivering products that stand the test of time.

Products

SPAC® Piece & Clinch Product

High Tolerance Cold Formed Shapes

Services

Product and Application Design

Tool Concepts

Production Line Automation

RB&W Careers

RB&W is always looking to add highly motivated and creative individuals to our global team.

Contact RB&W

RB&W

10080 Wellman Road

Streetsboro, OH 44241

Phone: (234) 380-8540

.png?width=249&height=70&name=parkohio-logo-1%20(1).png)